Hydraulic systems, cylinders, and components are used in several industries such as construction, manufacturing, railroad maintenance, marine equipment, agriculture, landscaping, and several others. When systems break down, hoses crack, or Hydraulic Parts in Chicago need replacing, those industries experience downtime, delays in production, and missed deliveries and service deadlines. Getting supplies and parts quickly saves both time and money. Experienced companies that offer supplies and repair services, such as Miller Hydraulic Service Inc, know to stock a wide variety of parts and cylinders in many different sizes and configurations.

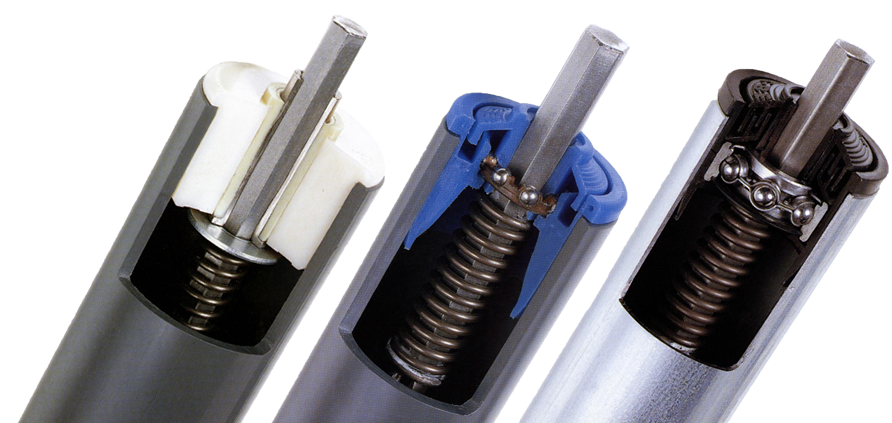

Inventory includes seals, chrome rods, packings, valves, motors, and pump replacement parts. Cylinders and tubes are available either honed or polished in cast iron, brass, nylon, copper, aluminum, and phenolic resin. Custom hydraulic hoses can be made on-site while customers wait. There are Hydraulic Parts in Chicago to accommodate any type and size of hydraulic machinery, equipment, and systems. Business owners who do not have repair technicians on staff can have repairs completed by experienced professionals. If the system is portable, it can be fixed in the shop and tested on state-of-the-art equipment prior to being returned to the customer. Power cylinders and dual pump testers put repairs through a testing of normal use to ensure stability and durability.

Machinery and systems that are not portable can be repaired, and field tested at the business location. Twenty-four emergency services are available to decrease downtime and keep all three shifts operating at maximum productivity. Preventative maintenance services are also offered. Keeping systems operating efficiently is the best way to prolong the life of hydraulic components, save money on major repairs, and avoid time-consuming breakdowns of machinery. Machinery downtime costs the business more than just time. When staff members are being paid to wait around for repairs to be done, delays in production will lead to unhappy customers, and penalties for missed deliveries can be expensive. Frequent breakdowns may even lead to a loss of contracts, loss of perishables or integrated components, and a decline in orders. Welding and metal fabrication services are also available to custom parts or equipment, make repairs rather than requiring replacement, and save money for the business.