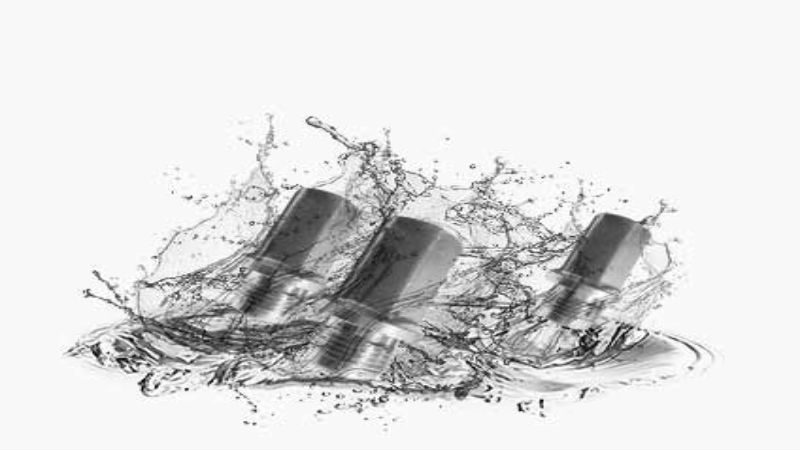

Aluminum is the most highly recycled item in the United States. This should come as no surprise. Soda (next to alcohol) is the most popular drink by a large margin, and many of these purchases are canned sodas. Aluminum Recyclers in Baltimore see incredible volumes of...